“Established in 1885, DENN (Industrias Puigjaner, S.A.) has 140 years of expertise in manufacturing metal forming machine tools.”

DENN: Innovation & Experience in Metalforming

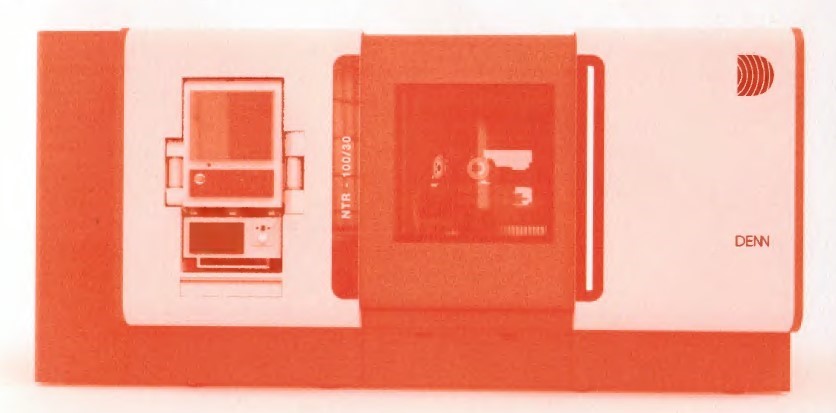

- standard to fully custom machines

- modern, fast, safe & flexible

- reliable construction & components

- custom & user-friendly software

- superb surface finishes

- superb repeatability

Your Partner

- Experience

- Innovation

- Service

- Trust

- Reliability

- Continued Improvements

- Relationship

More About DENN – Industrias Puigjaner, S.A.

EXPERIENCE

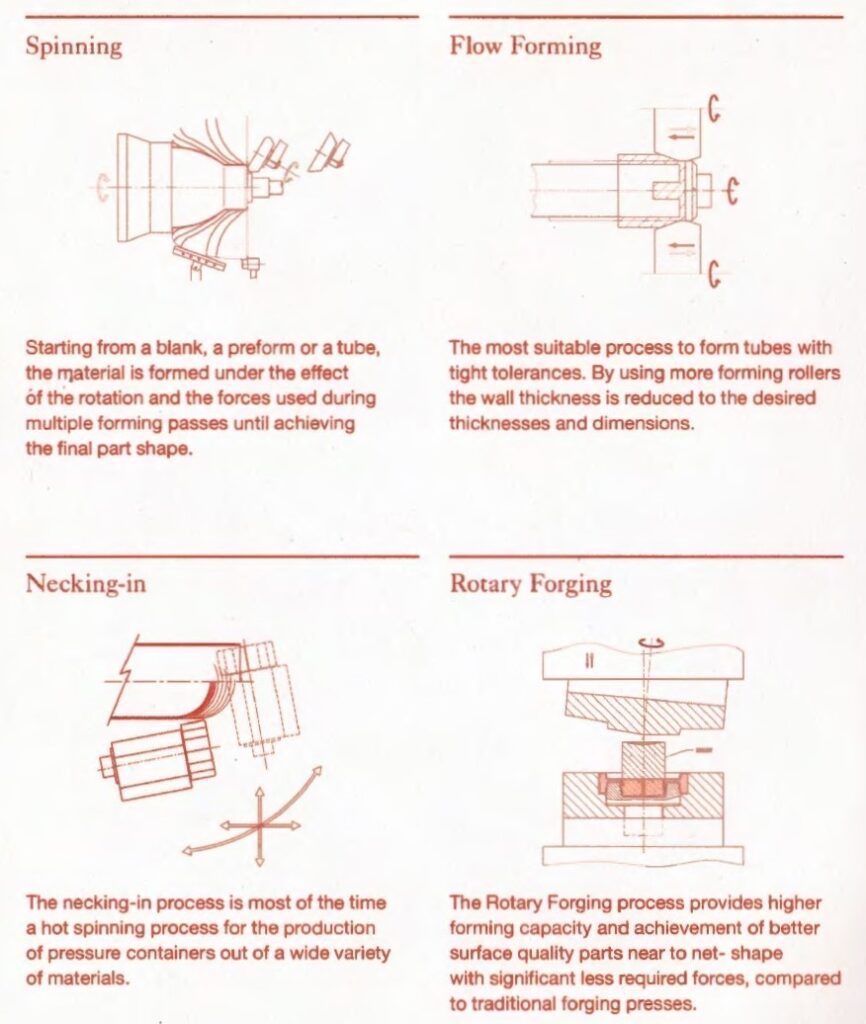

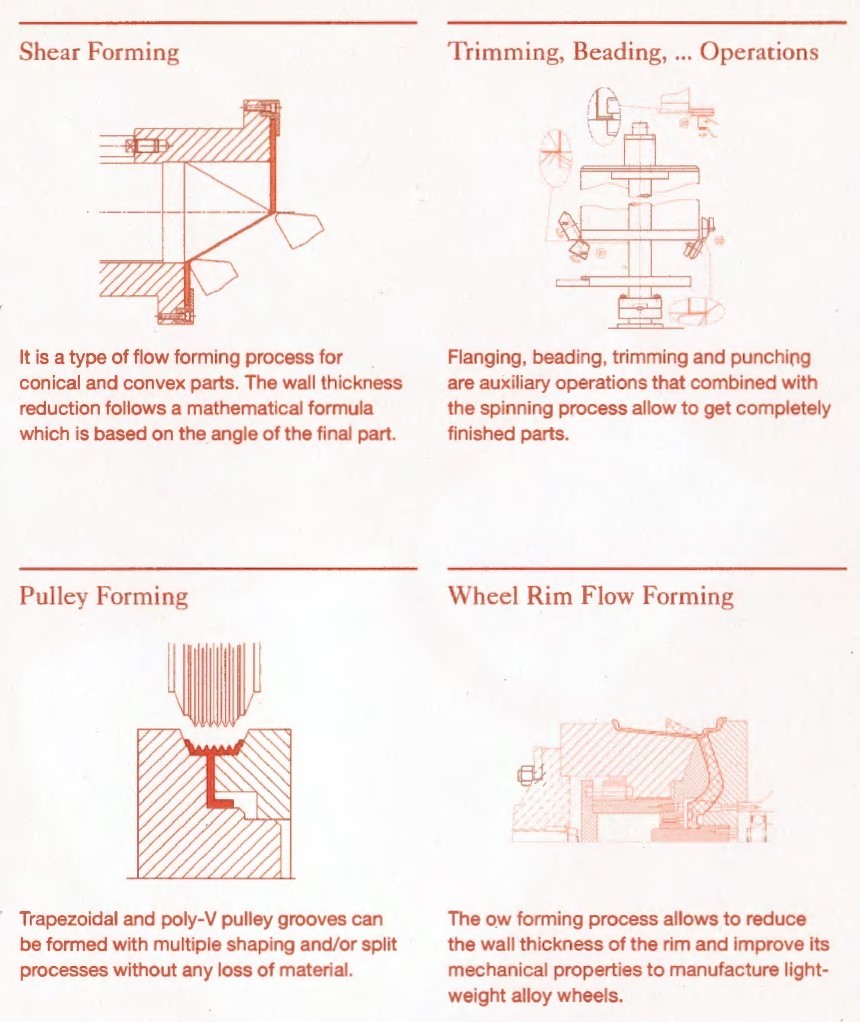

DENN is experienced and specialized in designing and manufacturing metal forming machinery for many different processes, such as spinforming, flowforming, necking-in and rotary forging. Our Process Engineering Team will study your requirements to provide the most suitable equipment and process support so that you can achieve the maximum possible productivity.

Industrias Puigjaner S.A. was founded in 1885 by Joan Puigjaner Jane as a family business. Pioneer in machine tool manufacturing, DENN built the first and oldest machine tool of Spain, where the company is based. Since the company’s foundation, DENN has been focused on metalforming processes development and metalforming machine-tools design and construction. As a family business founded in 1885, we strive for long term continuity. We integrate every colleague into the family business to have a pleasant work environment and therefore establish a very effective team. The continuous investment in R & D has allowed us to use the latest technologies to develop technical solutions that will provide more added value to our customers by offering them a complete service package in innovative processes and technologically advanced machinery and tooling, and having at their availability a team of after sales technicians. Excellence is our main goal and we firmly strive to achieve it. As leaders in “solutions for metal forming by rotational methods”, we want to be the best partner for our customers and share with them our technical capabilities and experience, from 140 years in customized designs with the aim of meeting customer specific needs. We align DENN to be the reference brand in the market: a recognized brand name standing for expertise, quality, technology and flexibility.

TECHNOLOGIES

The metal forming processes provided by DENN are metal spinning, flowforming, necking-in, rotary forging, trimming & beading and related processes. Starting either from blanks, tubes or preforms. And using a countless variety of materials such as aluminum, stainless steel, inconel, titanium, etc..

INDUSTRIES

DENN is present in countless industrial sectors, which include the most demanding and high-tech industrial sectors.

Automotive: Especially over the last 20+ years, our R & D department focused a lot on this sector, developing specific processes and machines for manufacturing of various components, in order to save material and cycle times in the manufacturing process.

Ventilation: Our technologies are highly suitable for this sector, which manufactures short to medium series, and they allow our customers to optimize their tooling costs, intermediate stocks and “overhead-costs”. Denn machinery is widely used in this sector.

Pipe, Oil & Gas: Pipe manufacturers for fluid transportation and drilling, in large quantities and long distances, use special anti-corrosive steels against high temperatures and other influences. To obtain the required parts thicknesses, manufacturers must start from preforms with increased thicknesses. With our flowforming technology, you can obtain your final product with no material loss.

Aerospace: Due to the characteristics of this sector, which requires short series production, special materials and important demands of accuracy, our technologies are highly suitable for it. Part of our investments in R & D has been devoted to investigate the behavior of these materials with our technologies.

Lighting & Building: We are suppliers of equipment for major companies in this sector, which have traditionally relied on the expertise of DENN. The spinning technology allows manufacturers in this sector to optimize tooling costs, intermediate stocks and “overhead-costs”.

Packaging: Our process department and technicians have studied countless manufacturing processes for multiple components in this sector. We have a lot of experience available for you to study your specific manufacturing process needs.

Chemical & Medical: This sector requires vessels and containers, among other components, manufactured with non-corrosive raw materials such as stainless steel. The technologies developed by DENN adapt perfectly to this kind of material work and it allows optimizing the costs of tooling, intermediate stocks and “overhead-costs”.

Houseware: Traditionally, DENN has supplied equipment to manufacturers of this sector, both for spinning and flowforming technologies as well as special equipment for auxiliary operations from other technologies.

SOLUTIONS

DENN is a company with a very simple concept: “to develop the best metalforming solutions.” Therefore, the best talents of our employees are required with the aim to achieve customized solutions with innovative technologies.

- optimization of the part manufacturing process

- mandrel design for achieving the ideal final part

- quality process, surface and finishing improvement

- cycle times reduction in manufacturing processes

- machine model definition for customer specific parts

- new machine developments for customer specific parts

- advising on both part manufacturing processes and applications

- turnkey projects fully adapted to customer requirements

- product and prototype manufacturing for validation

Process Engineering Consulting: Our process engineering consulting department enables DENN to define the most suitable process and machine capabilities to fulfill the requirements set by the customer. DENN counts on an highly experienced and knowledgeable process engineering team specialized in several manufacturing processes, technologies and applications. They will efficiently support and mangae your project through the most accurate analysis and design, which will help you to choose the best option for your business project.

Customized Services: Should you require any of the aforementioned services, please do not hesitate to contact the DENN Service technical staff, which is staffed by highly experienced DENN techncians, whose knowledge include all our range of machinery and all its technologies.

INNOVATION

DENN invests more than 7% of its turnover in international R&D projects with the cooperation of industrial partners and technological research institutes.

DENN data

DENN data (https://denndata.es/) is a web site developed to show you how your machine is performing at anytime from anywhere. It makes manufacturer-user relationships closer, as DENN can help you to improve production efficiency and show you how to better know your machine’s functions in order to avoid production downtimes.

Production Control: At any time, DENN Data gives you information about your daily, weekly or monthly machine’s production; it also informs you about the machine’s downtimes.

DENN Trace:

• You can make graphics of the process variables of any part you wish.

• You can export process data to your computer.

• You can compare parts processes.

• You can make a quality analysis of the parts.

• It helps to define your future machinery, knowing your needs better.

Energy: You will know the energy consumption of your machine and thus, you can calculate your parts’ manufacturing cost and improve your quotations.

Alarms – Maintenance:

- Study of the alerts trend on your machine in order to foresee the maintenance actions and need of spare parts.

- Information about the headstock bearings conditions. You’ll know when bearings need to be replaced.

- Indication of the working temperatures.

AFTER SALES

Service is in the basis of DENN’s business chore values and mission. Our mission is perfectly aligned with a longtime support in customer service, where the most important asset is the customer’s business. Inspired by this goal, Industrias Puigjaner founded the DENN Service department with the aim of tailoring solutions, such as technical service and advising, maintenance, diagnosis and spare parts supply.

TEAM

Our enthusiastic and professional team represents our best aim to achieve full customer satisfaction worldwide, always intending to improve and extend services to them.

GLOBAL PRESENCE

DENN, the global metalforming machinery leader, having successfully preformed thousands of projects in all 5 continents, has suitable and knowledgeable partners in your own country/ region.

BARCELONA, SPAIN

DENN’s world headquarters is located in Polinya (Barcelona), Spain. A city of culture, Gaudi architecture, visual arts, sports and Mediterranean gastronomy in a friendly environment at the seaside. Business in the best atmosphere.

Your Partner

- Experience

- Innovation

- Service

- Trust

- Reliability

- Continued Improvements

- Relationship

Global Metal Spinning Solutions, Inc.

DENN USA Metal Forming

Colorado Springs, CO, USA

DENN’s partner in North America

We are dedicated to delivering high-quality machine tools and products for metal spinning, flow forming, rotary forging and related technologies; continuous improvements, and the highest standards of customer service. Each project is meticulously analyzed to provide optimal production solutions and machinery for our clients. We have led and are leading numerous research and development projects on innovative metal-formed parts production methods and have played crucial roles in the engineering and manufacturing of new metal forming machinery technologies. Our achievements are reflected in the success of our clients and our esteemed reputation.

From initial project ideas to part design, from prototypes to large-scale production runs, from machinery sales and setup to comprehensive after-sales support – we are your trusted, knowledgeable partner in metal forming, guiding you through every phase of your production journey.

Our commitment to metal forming is evident in our passion and expertise. Our customers are not just clients; they are our trusted partners, benefiting from our extensive technology, knowledge, and shared success.

If you require fabricated parts through metal spinning, flow forming, or related technologies, instead of machinery, please reach out. We will connect you with the best-suited parts suppliers.

We invite you to join us as a partner.