Metal Spinning, Flow Forming & Related Metal Forming Machinery

DENN – Innovation & Experience in Metalforming

Global Metal Spinning Solutions, Inc. – DENN USA Metal Forming

Innovation & Experience in Metal Forming! From initial project ideas to part design, from prototypes to large-scale production runs, from machinery sales and setup to comprehensive after-sales support – we are your trusted, knowledgeable partner in metal forming, guiding you through every phase of your production journey.

Our commitment to metal forming is evident in our passion and expertise. Our customers are not just clients; they are our trusted partners, benefiting from our extensive technology, knowledge, and shared success.

If you require fabricated parts through metal spinning, flow forming, or related technologies, instead of machinery, please reach out. We will connect you with the best-suited parts suppliers.

Machinery, Support & Value Added Products

Metal Forming Machinery Sales

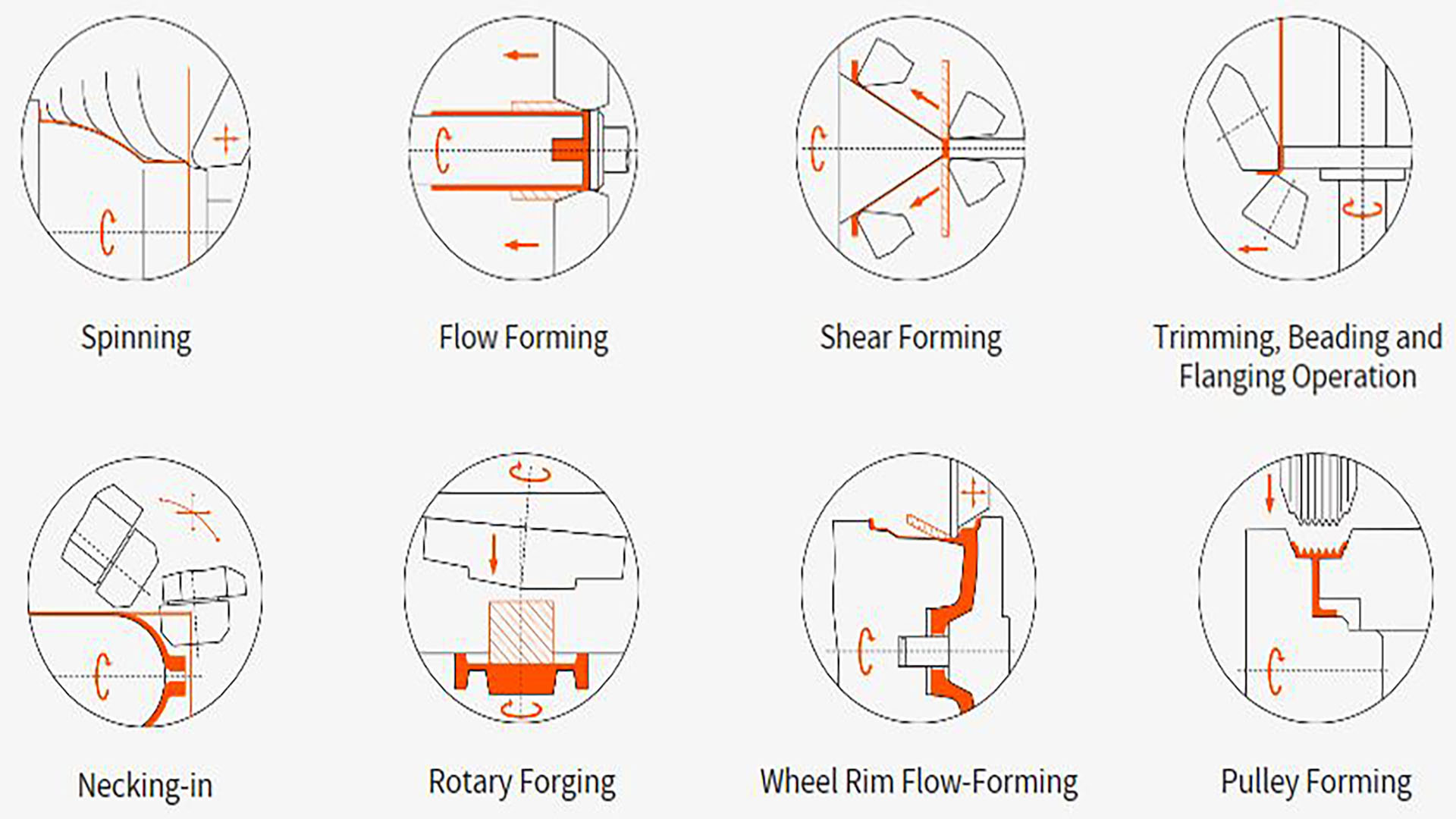

Metal Spinning, Flow Forming, Shear Forming, Trimming-Beading-Flanging Operations, Necking-In, Rotary Forging, Wheel Rim Spinning/ Flow Forming, Pulley Forming and custom forming machinery.

Metal Forming Machinery Support

Spare Parts, Training, Troubleshooting and Remote Assistance, Part Developments (Prototypes), Retrofits, Automation, Preventative Maintenance, Tooling Design and Manufacturing.

Metal Forming Lubricants

We sell Metal Forming Fluids and Solid Lubricants ideal for metal spinning, flow forming, deep drawing and related technologies. Protect your machinery and tooling wile producing great looking parts.

Technologies – DENN

machinery from standard to fully custom

Positional Precision & Repeatability

DENN machinery employs electrical driven slide compounds with movement performed by slides and transmission with a servo driven pressure spindle.

Electronic Pressure Control

DENN metal spinning machines are equipped with an electric pressure control system. This system can be activated by the programmer or operator to a constant force rate, thereby avoiding adverse effects caused by temperature and other changes.

Surface Finishes & Tight Tolerances

The integration of innovative and feature-rich DENN CAD-CAM programming software, precise positioning, electronic pressure control, and high-quality components enables our customers to achieve the best possible surface finishes and tightest tolerances in the industry.

Our YouTube Videos Playlist

Chipless Metal Forming Machines & Related Machine Tools

- metal spinning machines (spinning lathes, spinforming lathes)

- shear forming machines

- flow forming machines (flow Forming lathes)

- wheel forming machines

- rotary forging presses (machines)

- tube (cylinder / pipe) necking-in & closing machines

- trimming, beading, flanging, lock seaming, …, machines

- profiling & pulley forming machines

- circular (circle) and ring shears

- roll knurling machines

- custom metal forming machines

- used metal forming machines – retrofits

- automation & robotics

Our Metal Forming Methods

Some of the metal forming methods used on our offered machinery include: metal spinning (spinforming), shear forming, flow forming, internal spinning, hot metal spinning, spinning on air, spinning of unround parts, oval spinning, expanding, flanging, internal flanging, beading, trimming, edge setting, tube (cylinder) necking in, tube (cylinder) closing, rotary forging, reducing, swaging, profiling, splitting, folding, curling, beading, ribbing, lock-seaming, parting off, machining, groove turning, groove forming, thread rolling and additional related methods. Many of these methods can be used together in one cycle.

Services & Value Added Products

- metal forming (spinning) and deep drawing fluids

- solid wax-based metal spinning lubrication bars (spinning soaps)

- forge (hot spinning/ forming) sticks

- tooling engineering & manufacturing

- metal spinning & flow forming rollers

- DURASPIN® material sales

- metal spinning & flow forming training

- programming support & consulting

- on-site service

- remote troubleshooting & repairs

- spare parts

- research & development

- process development & simulations

- upgrades, retrofits, maintenance